Universal Windings Company was formed in the 1893 by Joseph Leeson to

manufacture machinery to put yarn onto patented bobbins designed by himself.

They moved to Cranston, Rhode Island in 1914, building a large manufacturing

facility there. The company trademark was the "Leesona" brand

machines and bobbins.  Initially

concentrating on machinery for the textile industry they adapted their

machinery to be able to make electrical windings for such items as radios

and electic motors.

Initially

concentrating on machinery for the textile industry they adapted their

machinery to be able to make electrical windings for such items as radios

and electic motors.

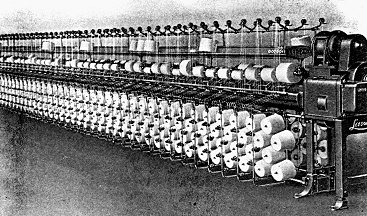

(left) The No. 60 Winding Machine is typical of the

kinds of products made by Univerasal Windings. This machine was used for

doubling multi-end packages of cotton, woollen or worsted yarns.

The machines wound the yarns around patented

bobbins called 'Roto-Coners' (right)

Customers of Universal "Leesona"

brand machines produced yarn spools like this -

During the First World War Universal Windings manufactured a variety

of products for the war effort including the hulls for hand - grenades which were produced in the foundry. These Government contracts

continued after the war period and included making items such as radios,

aircraft undercarriages, parachutes and weapons parts.

hand - grenades which were produced in the foundry. These Government contracts

continued after the war period and included making items such as radios,

aircraft undercarriages, parachutes and weapons parts.

Piling hand grenade hulls circa 1918.

The heavy engineering and foundry capabilities all to be found on

one site, plus experience working for the Ordnance Dept. attracted Johnson

Automatics in 1940 to use Universal Windings and their "Cranston Arms"

subsidiary as their production facility.

Universal Windings also sub-contracted to Underwood Elliott Fisher Co.

to make parts for the M1 Carbine. These parts included Receivers, Bolts,

Operating Slides and Hammers. Carbine collectors will recognise the 'W-U'

code used by Universal Windings to code their parts.