-

Content count

604 -

Joined

-

Last visited

Posts posted by M48TANKER

-

-

Yes, inquiring minds want to know?

-

Hey Art,

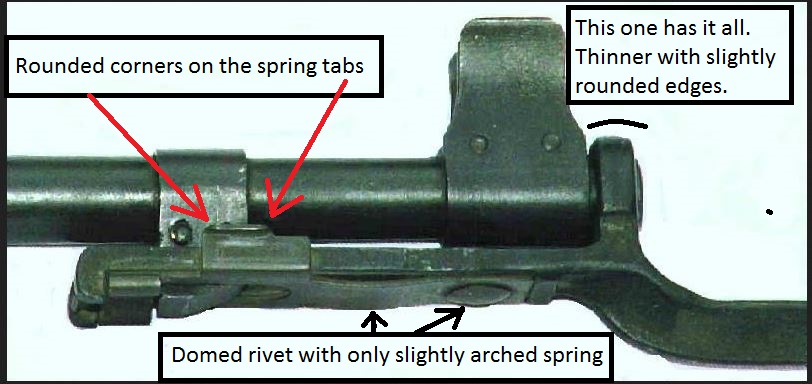

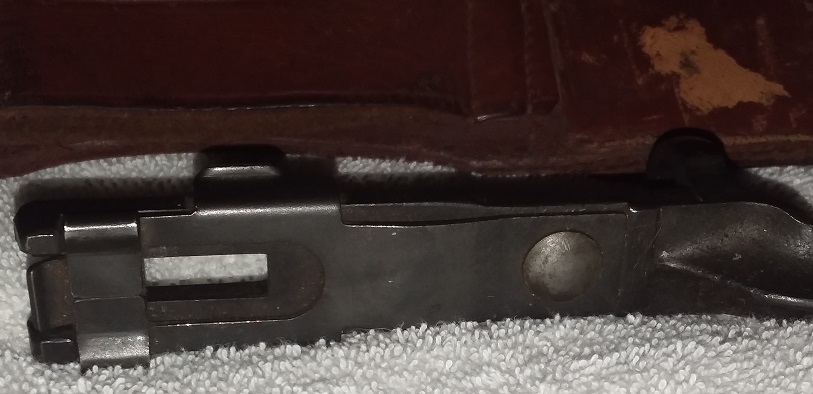

I agree on the scabbard but to me the bayonet is suspicious. It does LOOK old and well worn. But, check out the spring rivet, the heavier muzzle ring, and the little "tabs" on each side of the spring. Most all original bayonets I've seen have rounded edges on those tabs...this bayonet looks a tiny bit more squared up. From the bottom the spring appears to have a larger and more pronounced curve to it.

I'm certainly no authority on bayonets but I have studied diligently to be able to tell the difference myself....hehehe. I'll admit that I can't always tell the difference but these are my observations. If I'm sadly mistaken...please someone enlighten me!

If someone has created a "look-alike" they did a fair job of aging it.

-

-

Even if you have to make one...use a tool that fits perfectly in the slot of the main tube end cap. Make it tight...use a grinder to make the fit perfect. Then put something like a crescent wrench on the tool to apply counter clockwise rotation while holding the makeshift "screw driver" down tight.

If you can fashion something that fits tight you might be able to use a hand struck impact driver similar to ones used on motorcyles.

Take your time, don't let the tool rotate out of the slot. After unscrewing it the first time you can use some "anti-seize" to make the next time easier.

I made a similar tool years ago for the timing inspection cover on a Harley Davidson, and still have the tool today.

Just make sure that whatever you use fits the slot entirely....end to end and side to side.

-

roverboy,

Do you already have a bayonet lug and front sight?

M48TANKER

-

Huskytim2008,

Very interesting project and it's looking good. I saw that you make custom knives. My bucket list includes owning a Randall knife. I like the model 14 and the 17.

Have you ever made anything similar?

M48TANKER

-

Brian,

Great job on reshaping that stock. Particularly the round plug on the right side. You matched the grain about as well as could be done! That looks really nice.

What do you want for your other stocks? Thanks,

M48TANKER

Gleal,

Check your messages.

-

I've made a few barrels for myself out of 03 and 03A3 barrels. I've also altered a few Winfield Sporter barrels by the addition of the original front sights and bayonet lugs.

Putting the front sight and bayonet lug on a Winfield Sporter barrel is the easiest way to go for me.

There is a lot to consider when making barrels for commercial sale. Liability insurance would be prohibitive considering the very limited number of barrels you might sell.

If, God forbid, there was ever an accident with the rifle, you would be bankrupted by lawsuits whether the barrel was actually the cause or not.

If I needed a replacement barrel, I'd watch the board here and also on Gunbroker for an occasional barrel to show up. Be prepared to pay close to $1000.00 IF you find one.

A decent gunsmith, or anyone with the skills and a lathe, should be able to install an original sight and bayonet lug on your barrel without much trouble.

Joe Scott is legendary for the barrels he has produced. It takes a lot of skill and expensive equipment to make, chamber and headspace a new barrel.

I'm always on the lookout for decent original barrels or Winfield barrels which I can return to military configuration. You might check with me from time to time to see if I've found a usable barrel to sell.

I'm always glad to be of whatever help I can, as are Ed and Joe....and just about everyone else on this board.

-

JIm,

I've got to tell you that your craftsmanship is superb. Not only the wood work, but the metal finishing too!

M48TANKER

-

These pictures are not great but they'll have to do for now. I have noticed that the "Star" emblem on the holding strap rivet is like the Chilean Army star. Perhaps the Chilean Army made them or Chilean National Police? Look at the star shown in Yuccacapt343's second picture down. My sheath has that same "Star" on the rivet.

-

I am researching the Chilean bayonets and sheaths. There is not much to be found yet. I did find this posting from 2006:

-

I would love to know who made the Chilean contract scabbards?

-

Thanks Matthew,

I was glad to be of help.

TANKER

-

I have purchased the "dagarbuz" recoil tubes last year. They are a work of art. Every detail is just as the originals were and you'll be pleased.

I'm looking forward to the tube cap/buffer assembly!

-

I've spent the majority of my working life building high end custom homes. I do all kinds of woodworking from cabinet building, interior trim work, framing, and all finish work.

I will try to help anyone with their rifle restoration. I do have a lot of experience with the mechanics of firearms also.

Mike

-

I will be willing to assist Joe in reproducing Johnson stocks and forearms. I have some experience in reshaping and contouring Winfield Sporter stocks to resemble military stocks. Please let me know if I can help.

-

Renegadebgp,

Original stocks are very difficult to find and expensive when you do find one. There is an option, and that would be to re-shape the "sporter" stock to the dimensions of the military stock. I've done this several times. There are pictures in the "Gallery" section of this web site of what I did. http://johnsonautomatics.com/messageboard/index.php?/gallery/

Likewise your current barrel can be retrofitted with a bayonet lug and original front sight. These two parts are sometimes available from "Numrich"/"Gun Parts Inc." or "Sarco"

Most likely your present barrel is in pretty good shape internally, and a good candidate for adding a bayonet lug and front sight. (if you can live with a replacement barrel) especially since nice original barrels are currently bringing from $700.00 to $1300.00

Some of our members have extra parts from time to time, and have made "new" barrels from 03 and 03A3 Springfield barrels. Mr. Joe Scott is the world's best at reproducing these barrels. He can also use Garand barrels and other commercial 30.06 barrels.

Mr. Joe Scott is your best bet for restoring your rifle. If you can't contact him, I will try to assist you in your quest.

MIchael Roper aka "M48TANKER"

-

I didn't intend to bid anyway.

-

-

-

Congratulations on the completion of your new barrel. It does look great. There is such satisfaction in doing it yourself, not to mention the cost savings...er....that is if you don't count the time you invested in the project!

-

I've observed several different "original" barrel lengths. Most likely due to where you define the beginning and the end of the barrel. I think some "authorities" say the barrel is measured from the chamber face to the end of the muzzle. Others probably include the locking lug bushing in the length. Most all agree that the 1941 Johnson JSAR barrel is 22 inches at least. Many I've encountered are more like 22&1/4 to 22&5/8ths. I would measure from the face of the closed bolt to the desired end of the muzzle. That is what BATFE goes by.

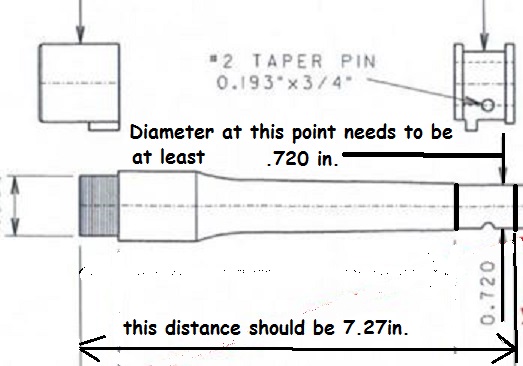

This is just one of many charts I've found on the internet listing barrel length as "22" inches. This chart adds .01 to that length. One thing is for sure....if you make it 22&5/8ths to include the locking lug bushing, and later decide to make it shorter, you will have the extra length to work with. The most important measurements now for your project are the location of the center guide bushing, bayonet lug, and front sight. At the bottom of this posting I'll quote Joe Scott for those measurements.

And here is a diagram:

All this being said: Check the inside diameter of the parts you are going to install before just turning the barrel down to specs on paper. Turn the barrel down to diameters which make a tight friction fit with the parts of be installed.

-

With a little TLC it could look better.

-

Orlando,

I hope that someone has a few extras to sell. Several of us have been making our own over the years. I made a couple for myself from the steel banding that sometimes comes clamped around pallets, cartons, etc.

I got my donor material from the local lumber company. You should find this banding at most any retail store as scrap.

I had to anneal (heat) the banding in order to bend it to shape. Then heat it again to return it to it's former hardness.

Let us know what works for you.

in Johnson 1941 Rifle

Posted · Report post

Camstuff,

I can't see the portion of the forearm that would reveal the origin. If it has a notch for the front magazine pin, it might be original. But from what I can see it's probably a Winfield or replacement.....which is easy enough to reshape into a military configuration.; Another thing to be aware of is that the stain/finish on a factory Johnson was a "dipped finish" which stained and sealed all the screw holes and ends of the wood. If you can see lighter color bare wood showing in these recesses, chances are that it's a reproduction.

Also the "split spring pins" holding the front sight and bayonet lug on the barrel are definitely wrong. They should of course be solid "taper pins" and would have made the rifle far more pleasing to the eye. (of the beholder)